Non-woven Industries Development. Non-woven fabric was invented in the petrochemical industry following the development of plastic cloth (film). It weighs less than plastic cloth and offers better airflow. It is used extensively in medical and personal hygiene products like filters, facial towels and sanitary napkins. The technology was further developed and later applied to engineering. Non-woven fabrics protect vegetables from damage caused by cold. The production process of non-woven fabric is different from plastic film, however the basic raw materials are almost the same. It comprises PVC (polyvinyl chloride), PE (polyethylene), EVA (Ethylene Vinyl Acetate copolymer), PVA (polyvinyl alcohol) and other such items. You can create a thin plastic film from conventional plastic by melting it, then inflating. It is continuous. It extends indefinitely. It is smooth and does not have pores. It is a totally impermeable substance that blocks the movement and exchange of molecules. Following the expansion of the textile industry, artificial chemical fibres made from the ingredients mentioned above became the new darlings of the industry of textiles. They are made into cloth through traditional warp and weft weaving. Non-woven materials are created by combining fibers in the same plane at different angles in every direction instead of using traditional warp/weft methods. It has better properties for the material and is less difficult to make than traditional woven materials. It's cheaper than traditional weaving, which involves weaving yarn into fibers and weaving. The apparel industry has been using non-woven materials in large quantities in recent times. Non-woven fabric has been used in a broader range of applications over the past few years due to advances in production and material science technology. We see the diverse types of materials and products used in each day life. The expansion of the use of non-woven textiles in agriculture is due to their lightness, easy production, low-cost, diversity, and wide application possibilities. See this non woven weed fabric for advice.

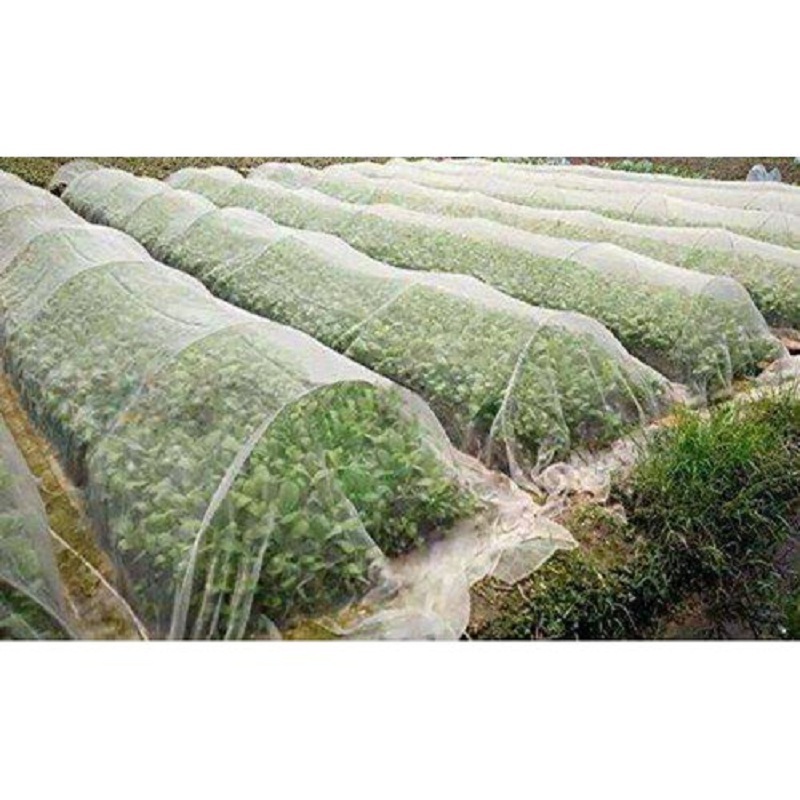

Non-Woven Fabrics for the Agricultural Industry. Non-woven fabrics first appeared in Europe in the year 1978. They were utilized to keep carrots warm in early harvesting and to stop the spread of tomato leaf virus and whiteflies. Non-woven textiles in the United States are used for mulching sweet peppers, cantaloupes, tomatoes and root vegetables. They are mostly used to preserve heat, for early harvesting, as well as insect control. Non-woven materials are often employed as covers for surfaces, such as grass-proof mats. To ensure that roots fully absorb water, short fibers can be used to create blankets that are water-absorbing. They can be used for the ground medium for turf production. They are also used as plant bags to accommodate large trees, such as garden trees and fruit trees. Non-woven fabrics are commonly used in Taiwan as crop covers. They are also used for the environment control of large greenhouses in order to reduce energy consumption. Double-layered canopy and cover curtains minimize solar radiation and heat dissipation in the evening. At first, TAVIK non-woven spun-bonded TAVIK fabrics of high density were employed to shade and shield cauliflower bulbs. They quickly adopted it by farmers due to its thermal conductivity that was low as well as capacity to shade. It was later used to protect leaf vegetables as well as their insect-proof cultivation. Later it was used to shade, heat and protect fruit trees as well as pineapples. Due to Taiwan's unique climate and climate, non-woven sector growth is slow. Taiwan's nonwoven fabric manufacturers are constantly innovating in nonwoven technology. This is a case of air permeability, absorption of water, as well as water repellency. It is utilized to store and preserve agricultural product. Follow this agriculture non woven fabric suppliers for recommendations.